Acceptable Quality Limit (AQL)

What Does AQL Mean?

‘AQL‘ stands for ‘Acceptance Quality Limit‘, and is a method used by many businesses to check a random sample from the production batch of their products and confirm that the risk of bad quality is relatively low. In ISO 2859-1, the AQL is defined as the “quality level that is the worst tolerable.” It represents the maximum number of defective units, beyond which a batch is rejected. Importers usually set different AQLs for critical, major, and minor defects. Most Asian exporters are familiar with this type of setting.

For example: “AQL is 1.5%” means “I want no more than 1.5% defective items in the whole order quantity, on average over several production runs with that supplier, and I accept a certain amount of risk that I make the wrong decision based on the imperfect information coming from checking only a sample of the whole batch”.

Before using the AQL tables, you should know three parameters:

1. The ‘lot size’: If you ordered different products, consider each product as a separate lot. (The quantity of each product is the lot size). If you ordered only one product, the lot size is the total batch quantity.

2. Inspection level: Different inspection levels will command different numbers of samples to inspect. In this article, we will stick to the so-called “level II” under “normal severity” and to single sampling plans.

3. The AQL limits: The AQL limits appropriate for your market. If your customers accept very few defect, you might want to set a lower AQL for both major and minor defects.

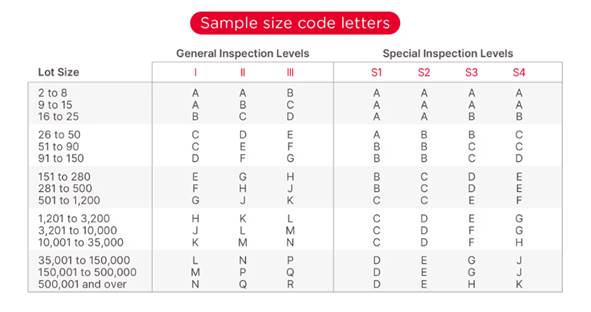

Table I:

Find the respective Lot Size (quantity) and general inspection level: Code letter L Note: The AQL tables below are based on the ANSI/ASQ Standard Zq.4 – 2008

How to read this table?

If you follow my example, I assume your ‘lot size’ is comprised between 3,201 pcs and 10,000 pcs, and that your inspection level is ‘II’. Consequently, the code letter is “L”.

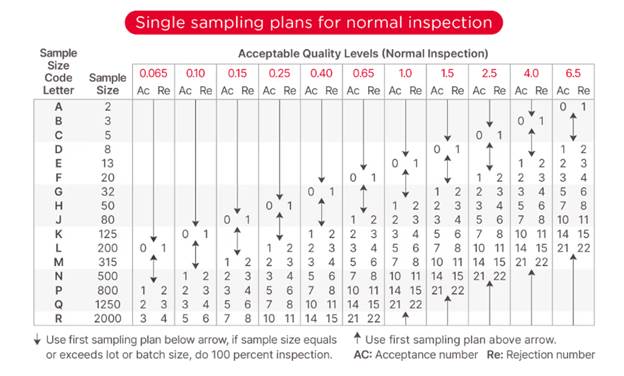

Table II:

Locate Row L (the required sample size of 200) In compliance with AQL 2.5, no more than 10 units from a sample size of 200 may fail the inspection.

How to read this table?

Our code letter is “L”, so you will have to draw 200 pcs randomly from the total lot size. Besides, I assume you have set your AQL at 2.5% for major defects and 4.0% for minor defects. Therefore, here are the limits: the products are accepted if NO MORE than 10 products with major defects AND NO MORE than 14 products with minor defects are found. For example, if you find 15 products with major defects and 12 products with minor defects, the products are refused. If you find 3 with major defects and 7 with minor defects, they are accepted.

Note: in quality inspections, the number of defective products is only one of the criteria. It is sometimes called “quality”, or “quality findings”. The other criteria are usually on the inspector’s checklist, which typically includes:

AQL Calculator

We usually help our clients to select the most suitable inspection levels and AQL limits, but you can use our calculator below (based on the AQL tables) to get a fast answer.

Fill in the calculator to easily find your perfect sample size (the number of pieces that should be randomly checked from the lot being examined) and the number of major and minor defects that can be tolerated based on your AQL specifications.

(This quotation is from the August 28, 2018 by Mr Renaud Ạnoran- Quality inspection.org)